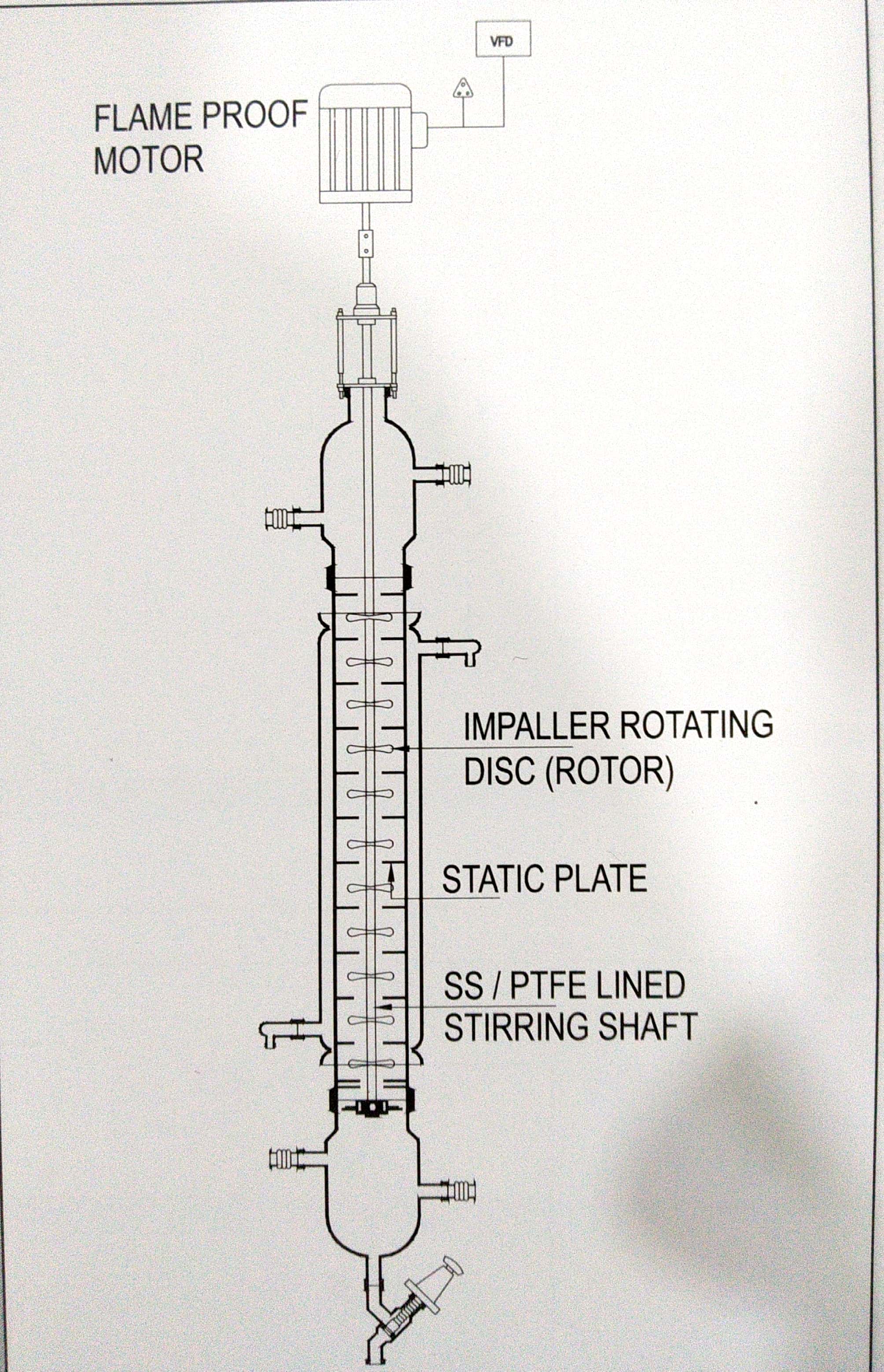

ROTATING DISCK EXTRACTION COLUMN

Separation will be carried out normally with the help of distillation but when it is not feasible by distillation or ineffective liquid-liquid extraction is one of the process to consider. There few mixtures are having close boiling points components or heat sensitive components which can not withstand the temperature of distillation, even under vacuum may also separated from impurities by extraction which utilize the chemical properties like specific gravity, solubility etc. instead of vapour pressure differences.

Separation by liquid-liquid extraction can be defined as the selective removal of one or more components either from a homogenous liquid mixture or from a solution, using a second liquid or solvent, which is partially or wholly immiscible with the first.

ConstructionThe core of the unit is a rotating disc with varied no of stage between 1 m to 2 m height. The RDC blade can be made of PTFE or SS304 or SS316 depending on the customer requirement.

The system can be supplied with or without dosing pump and two feed vessels as well as two receivers. The drive used for rotation of the disc is a standard geared- motor with an AC speed regulator. The agitator shaft is sealed by means of a mechanical seal.

The outer column can be constructed as a jacket pipe or without jacket as per the customer specification depends on the flowrates and the properties of the chemical used.

|

model

|

Size

|

Size DN (mm) Height

|

|

RDC3

|

80

|

2.0

|

|

RDC4

|

100

|

2.0

|

|

RDC6

|

150

|

2.0

|

|

RDC9

|

225

|

2.0

|

|

RDC12

|

300

|

2.0

|

|

RDC12

|

300

|

2.0

|

|

RDC16

|

400

|

2.0

|