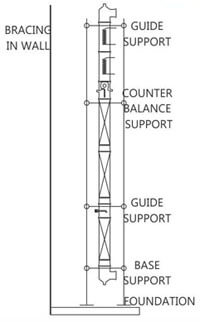

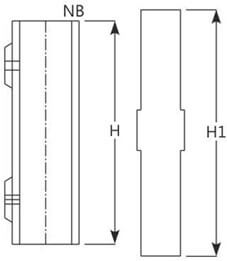

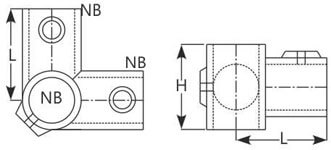

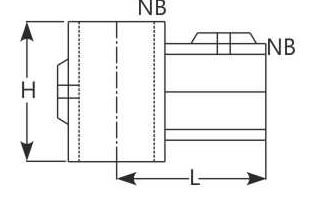

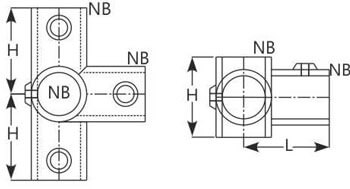

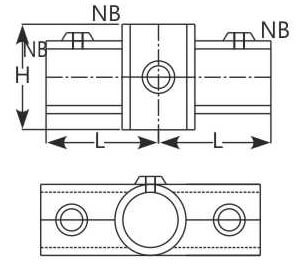

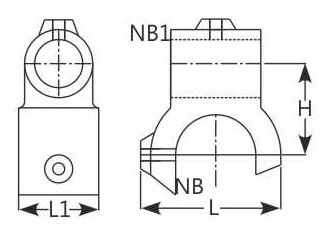

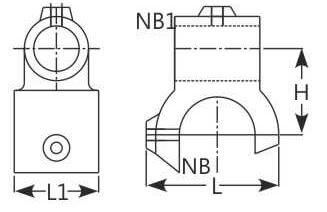

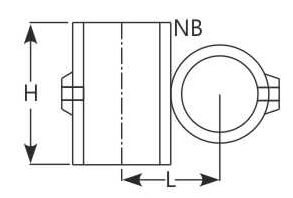

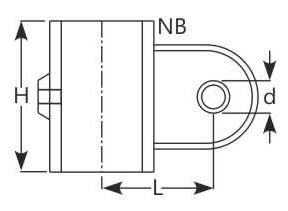

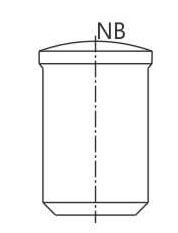

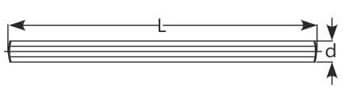

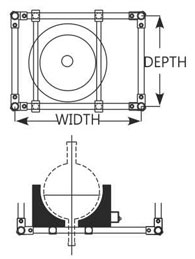

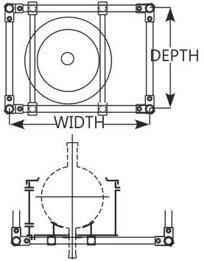

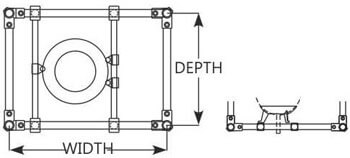

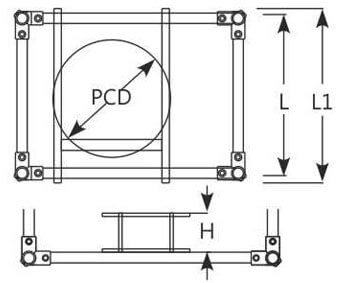

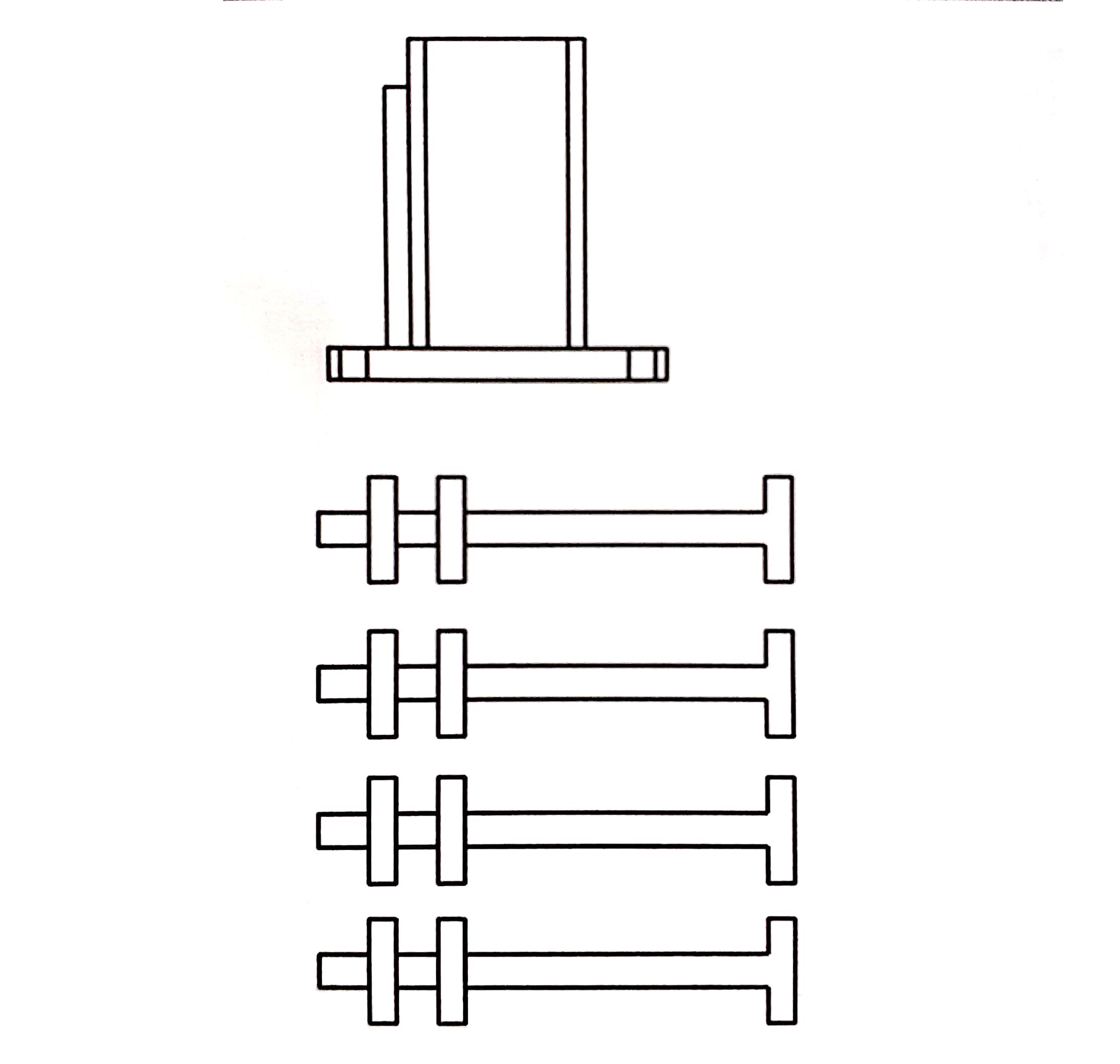

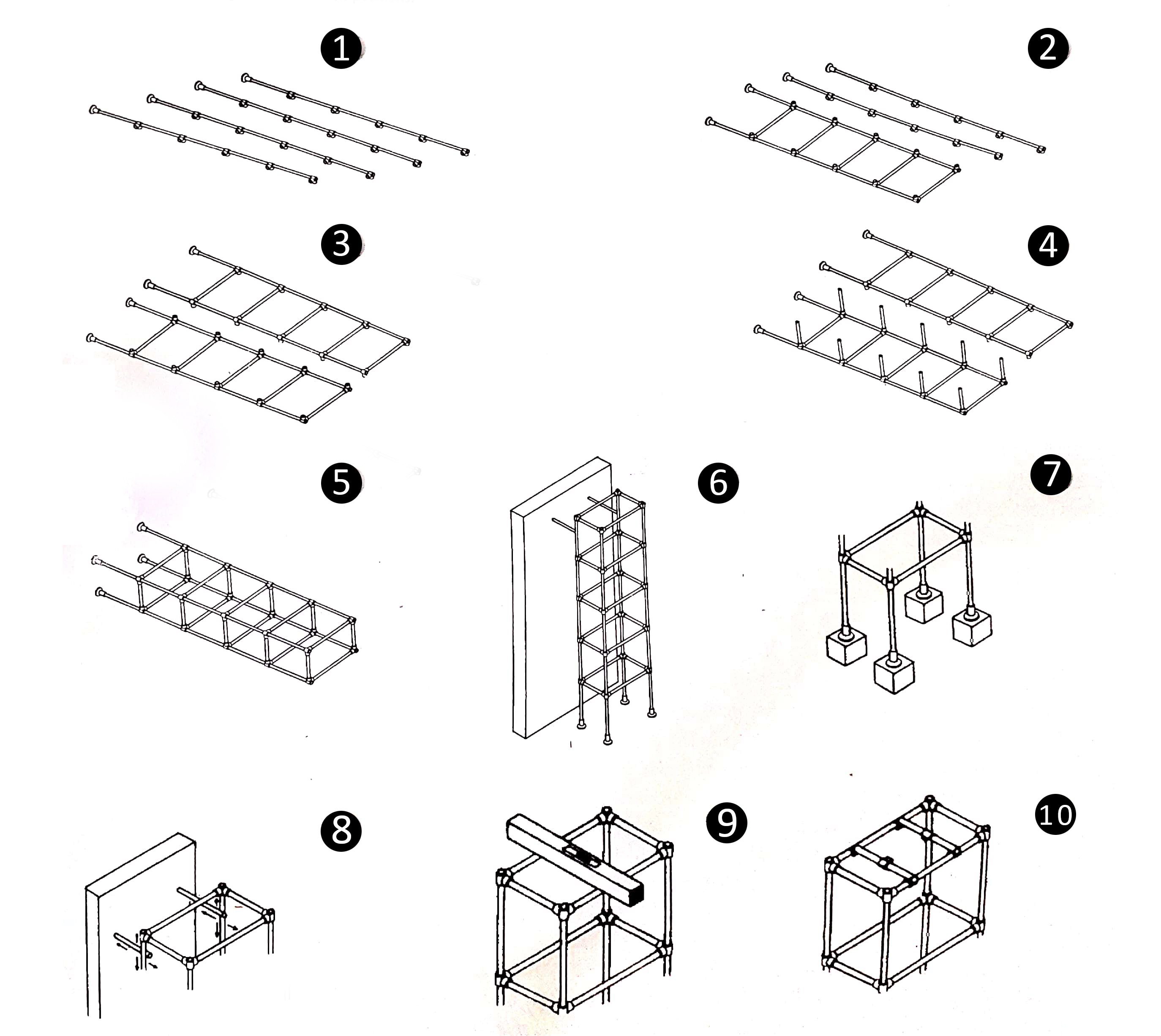

Glass plants are normally supported in a tubular structre formed of galvanised steel tubes. This type of structure is proved robust and flexible over many years.

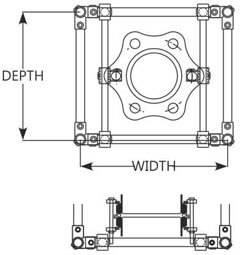

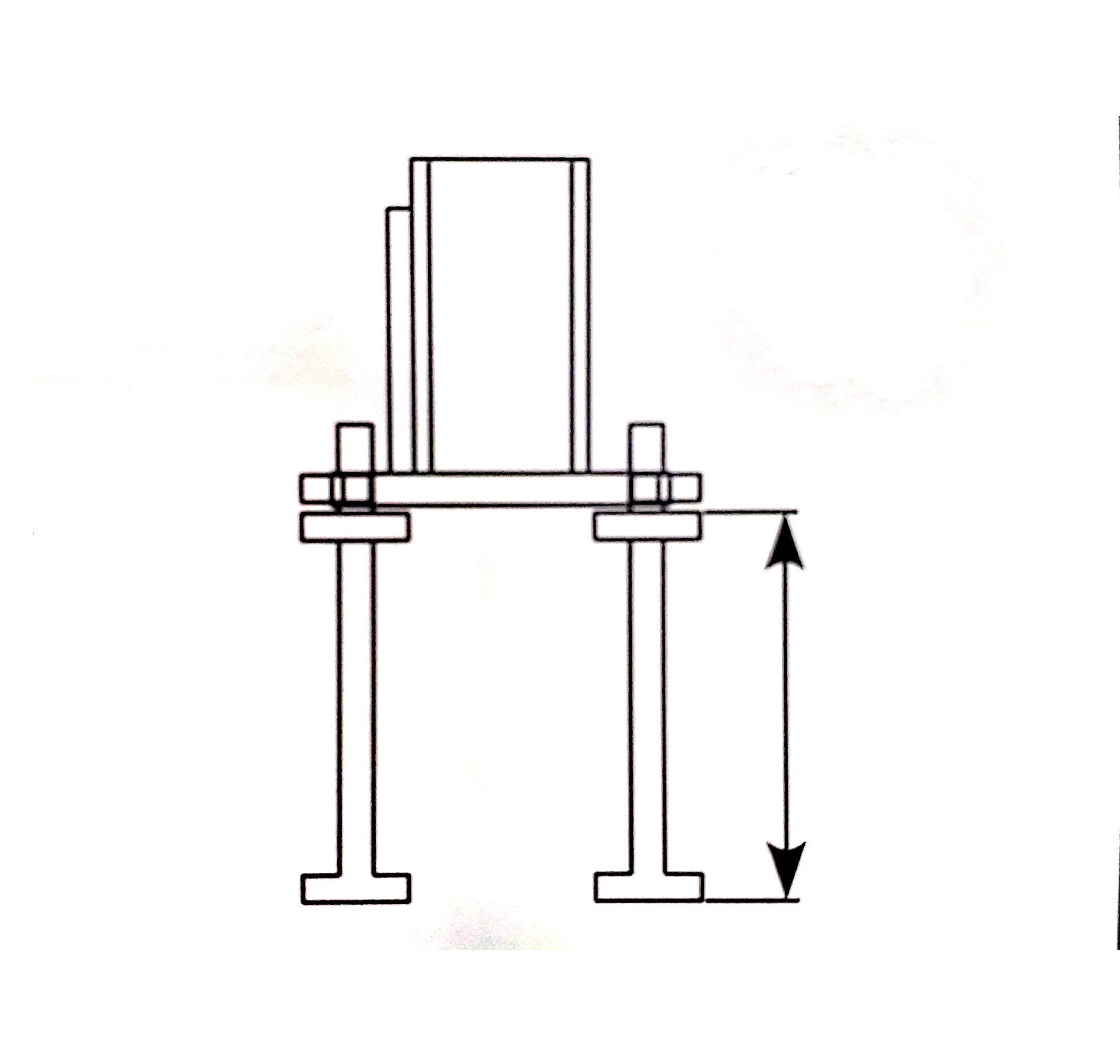

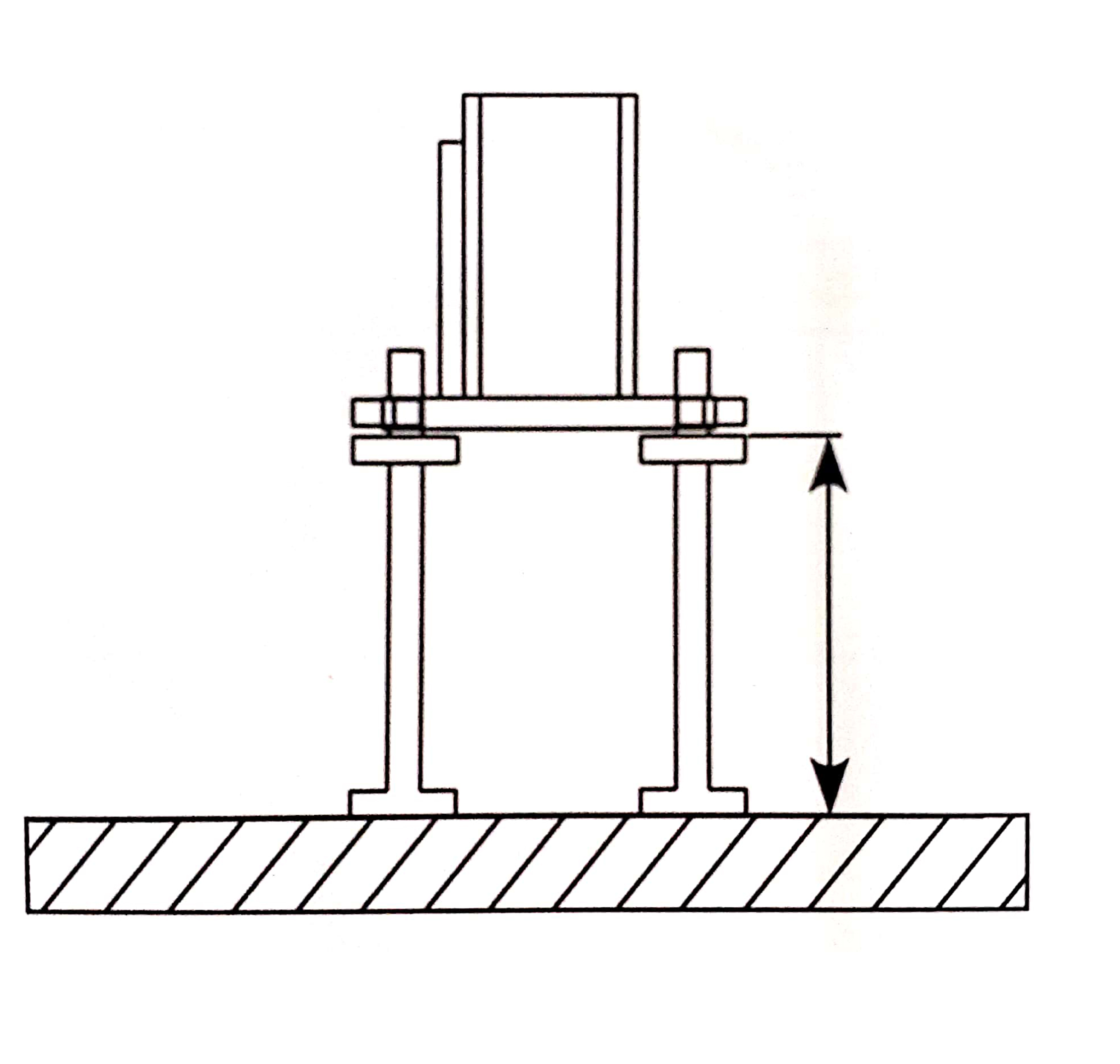

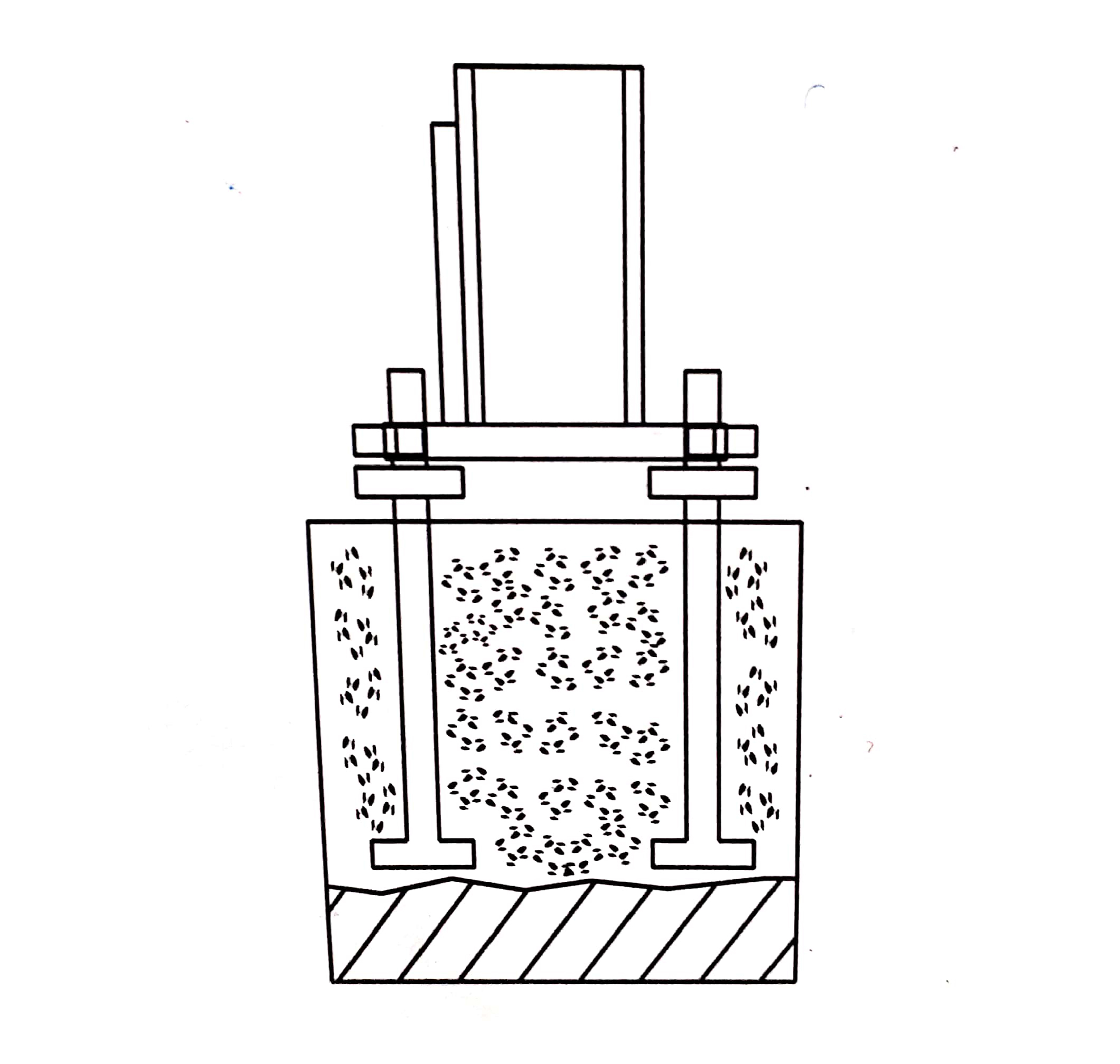

SUPPORT OF COLUMNGlass plants and pipeline should be supported correctly. To prevent inducing undesirable stresses in the glass, support should be rigid. When supported, glass should be in compression.

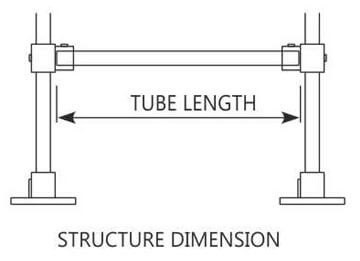

Generally, glass plant and equipment are supported in a rectangular tubular structure. This structure is formed of galvanised mild steel tubing with the cast iron fittings which are described in this catalogue. This type of structure provides enough flexibility for future modifications and is strong enough to support a glass unit.