BROMINE RECOVERY SYSTEM

Bromine is available in the sea bittern,as well as Industrial waste e.g.Aq.HBr / Aq.NaBr/Aq.KBr.The Bromine concentration in the feedstock varies from 2gpl to 300 gpl from industry.

Shorya Offer suitable bromine recovery plan for the various feedstock based on his 20 years expertise in this field.Shorya suggest cold process for bromine concentration below 3 gpl and Hot process above 3 gpl.

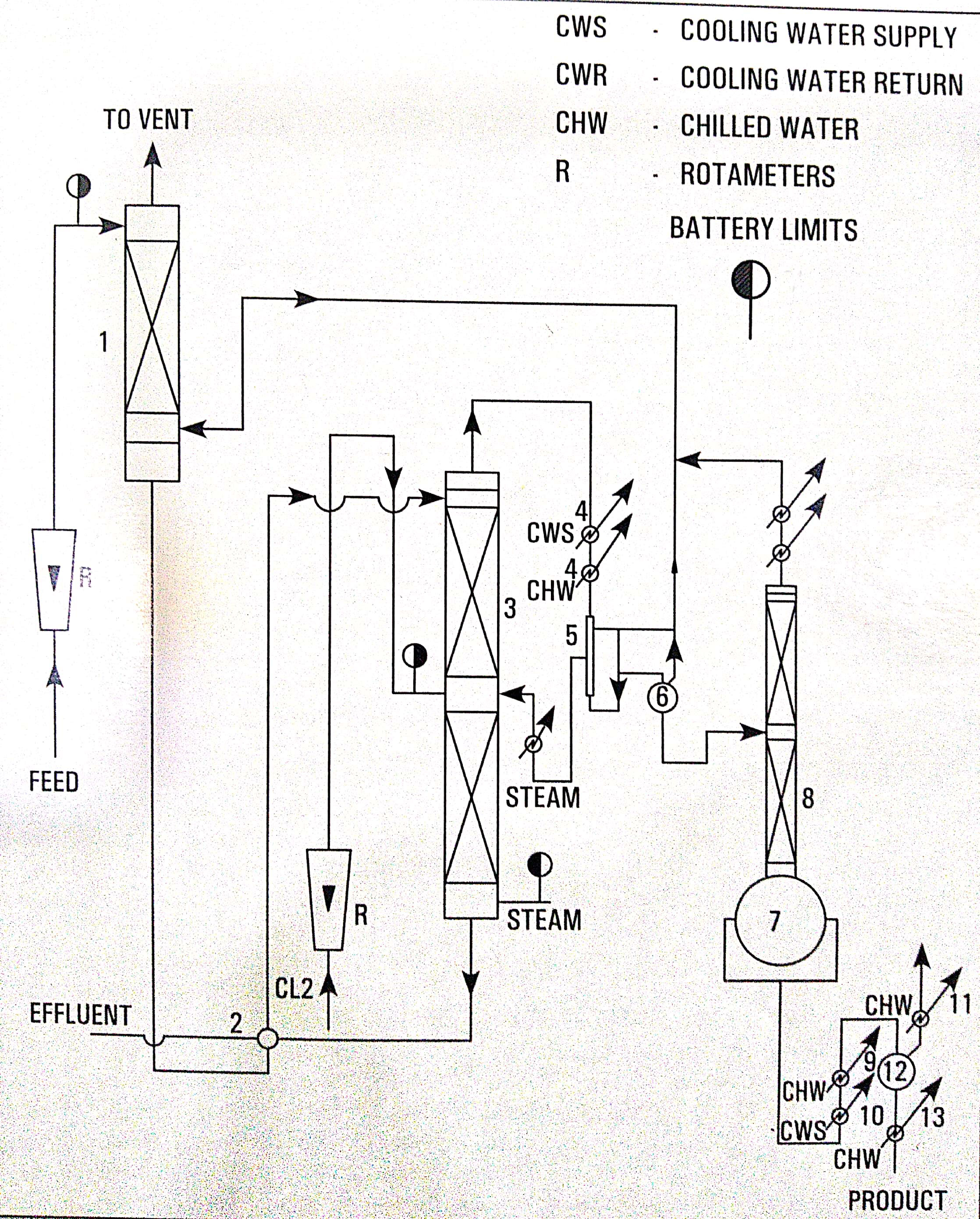

The package considered is schematically shwon in drawing enclosed herewith.

The process consists of simultaneous chlorination & steam blowing. The feed stock acidie in nature is preheated to near its boiling in feed pre heater and then fed to the main column where steam and chlorine are blown simultaneously. The bromine as set free by chlorine are steam distilled. The liberated bromine together with steam and some excess chlorine is condensed in the condenser. The condensate is taken to a gravity separated.while bromine is taken is the purifiction column the aq. layer is recycled into the main column.Crude bromine is purifide under reflux and pure bromine is collected in the receiver.All uncondensed vapour pass througt the tail scrubber to recover the last traces of bromine.

1. TAIL SCRUBBER 2. FEED PREHEATER 3. Br2 STRIPPING COLUMN 4. Br2 CONDENSERS 5. PHASE SEPERATOR 6. CRUDE Br2 RECEIVING VESSEL 7. REBOILER 8. PURIFICATION COLUMN 9. PRODUCT COOLER 10. PRODUCT COOLER 11. VENT CONDENSER 12. PRODUCT RECEIVER VESSEL 13. PRODUCT COOLER