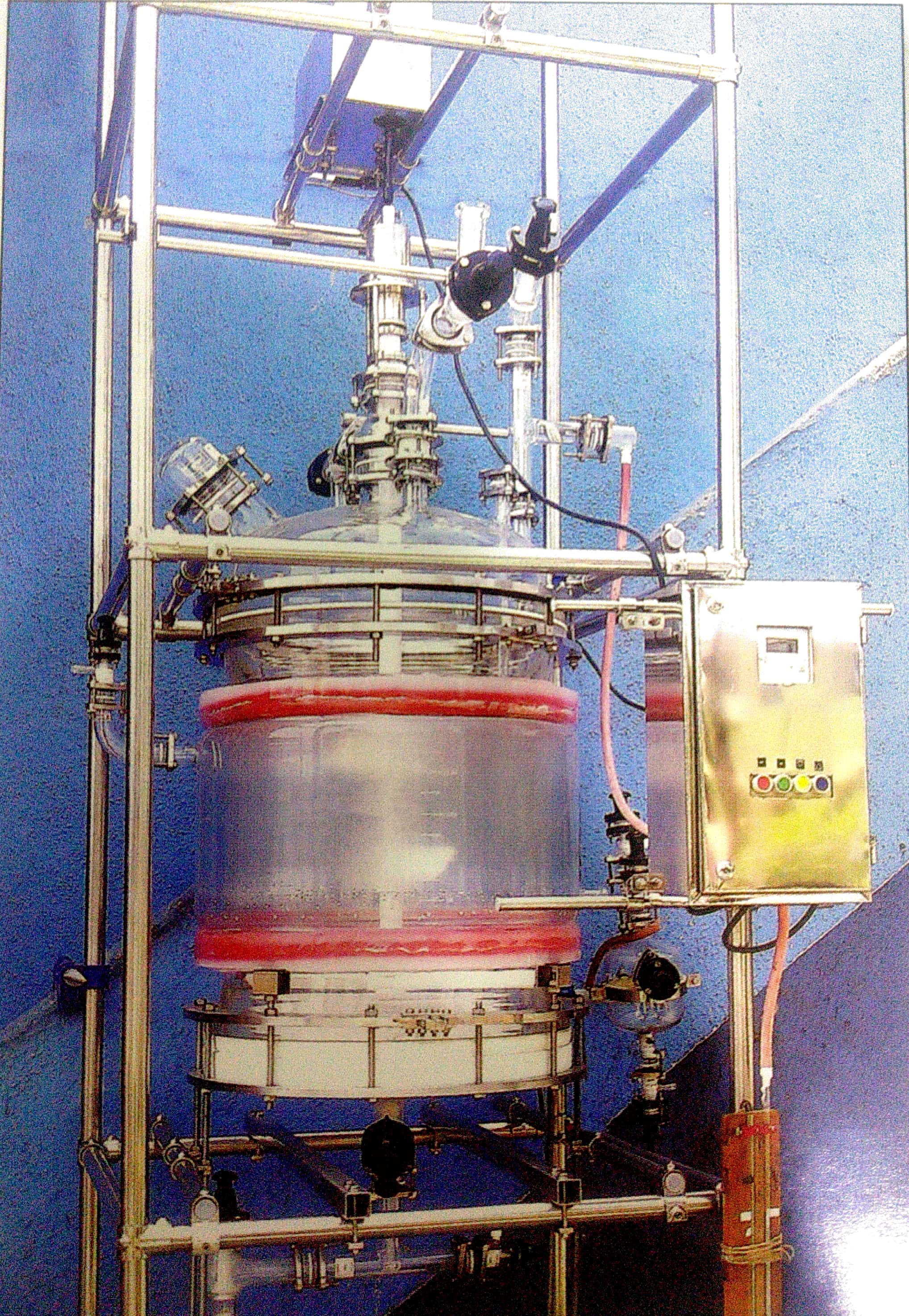

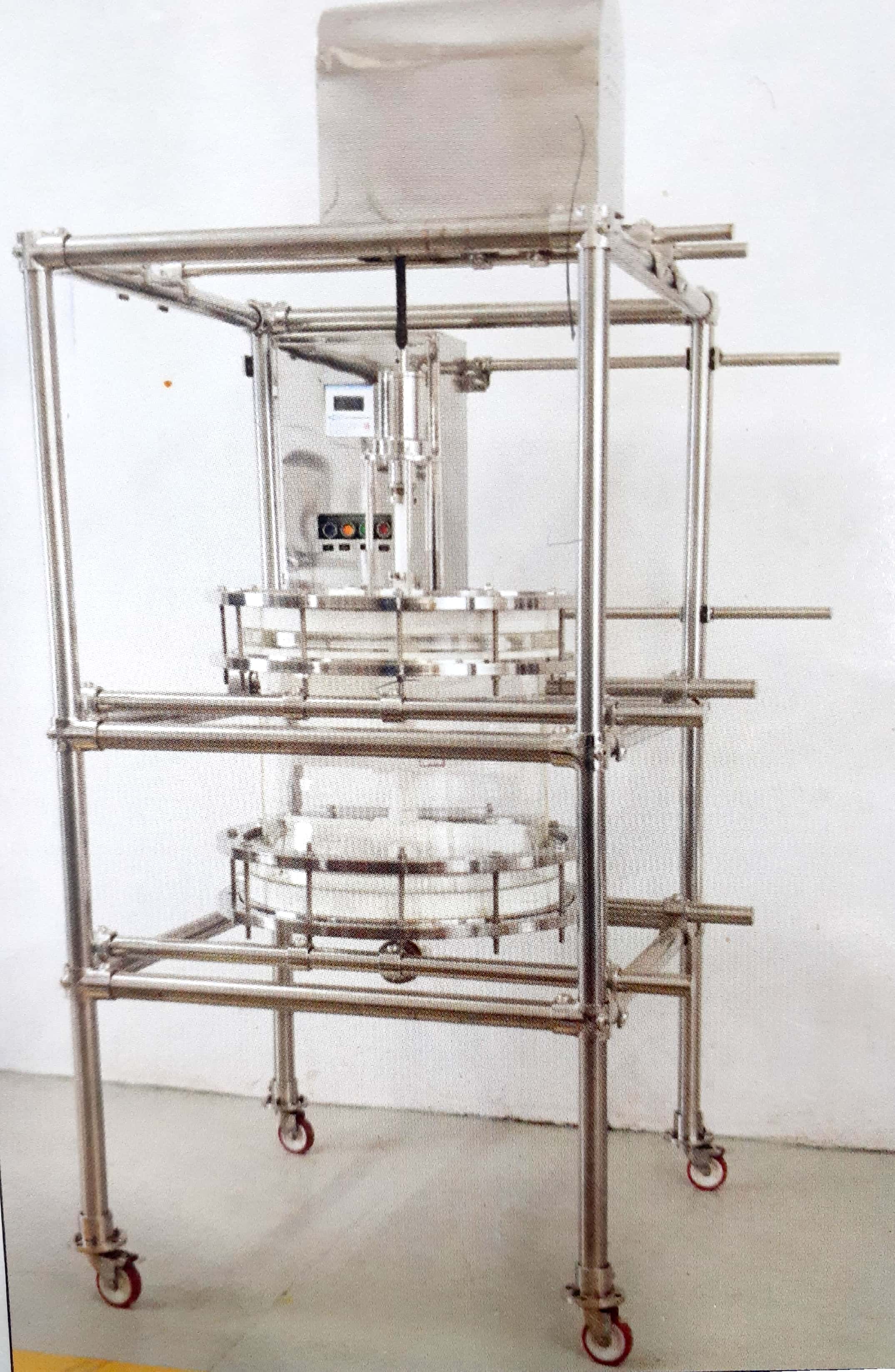

AGITATED GLASS NUTSCHE FILTER/ PEPTIDE SYNTHESIZER

Agitated Glass Nutsche filter is a closed vessel designed to separate solid and liquid by filtration under vacuum. The closed system ensures odorless contamination free and non-polluting working conditions maintaining product purity and hygiene. Agitated Nutsche Filters are expensively used in Herbal products, Chemical product development, Kilo lab operation, pharmaceutical manufacturing, argo chemical and the food industry.

GENERAL DESCRIPTIONA typical unit consists of a dish shape vessel with a perforated plate. The entire vessel can be kept at the desired temperature by using a mixer / agitator and jacket. It’s completely leak-proof for vacuum or pressure service. The base plate is having arrangement of boiling bar to hold the filter cloth. Suitable nozzles ca be provided including manhole and side discharge nozzle. PTFE Lined Stirrersare used for Agitator shaft and solid PTEF blades are used to take high torque generation during solid discharge and re-slurring operation. Drive assembly consist of motor with differences nozzles, Manual/Hydraulic system is provided for movement of agitator as well as bottom plate. PTEF Filter Support Plate.

PROCESS STEPS OF AGITATED NUTSCHE FILTER WITH AGITATOR:

1) Filtration

2) Washing of filter cake

3) Repeat mix or washing of the cake

4) Convection drying of the cake

5) Smoothing with compression of the cake

6) Discharge of the wet or dried cake

Vacuum filtration possible .

Glass being transparent, offers visibility of processes.

Insert gas atmosphere can be maintained.

Minimal contamination of the cake.

Very high solvent recovery.

Solvents are closed systems, so no toxic vapors are left off in the atmosphere.

Personal safety is maintained, and heat transfer surfaces can be provided to maintain filtration temperature.