Jacketed Pipe Sections

Glass Jackets

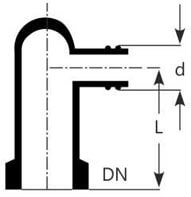

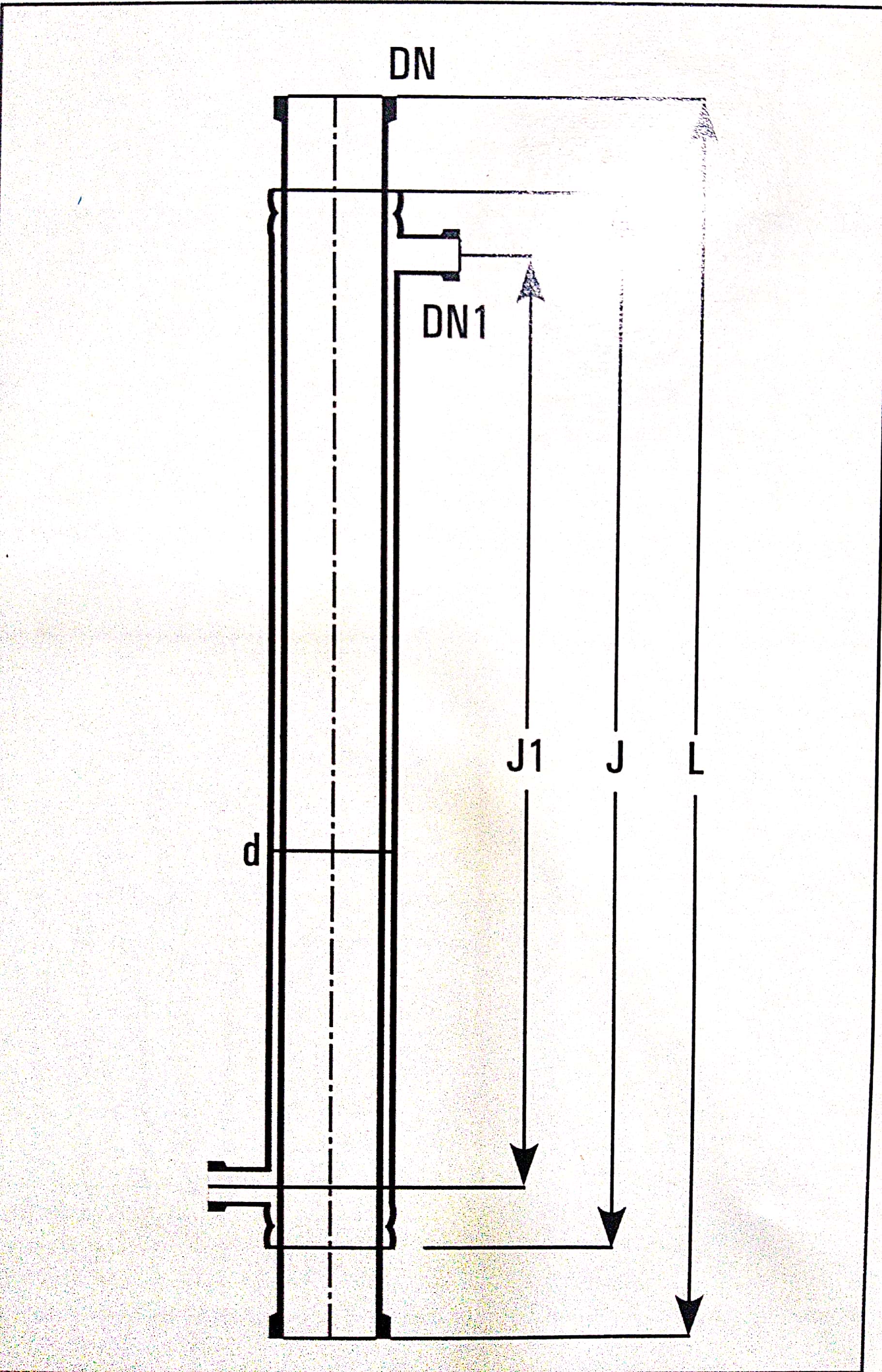

For heating of pipe and for controlling the temperature throughout the column, the jacketed pipe sections are provided. Glass jacket is sealed to the pipe section using Viton 'O' ring and other sealing compositions. The seal prevents impermissibly high stresses between two tubes and allows the movement which comes due to thermal expansion. Maximum operating pressure in the jacket :

|

DN 80 - DN 150

|

1.0 bar | |||||

|

DN 225 - DN 300

|

0.5 bar | |||||

|

Cat.Ref.

|

DN

|

L

|

d

|

DN1

|

J

|

J1

|

|

PSD3/1000

|

80

|

1000

|

100

|

25

|

850

|

750

|

|

PSD4/1000

|

100

|

1000

|

150

|

25

|

850

|

750

|

|

PSD6/1000

|

150

|

1000

|

225

|

25

|

850

|

700

|

|

PSD9/1000

|

225

|

1000

|

300

|

25

|

850

|

700

|

|

PSD12/1000

|

300

|

1000

|

400

|

25

|

850

|

650

|

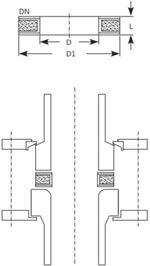

When reactors have a curved end nozzle, these adaptors are used as interface spacer to connect the glass/bellow with reactor. A flat metal ring with rubber cusions is enveloped with PTFE, to provide ideal sealing. Only PTFE comes in the contact of process fluid.

|

Cat.Ref.

|

DN

|

D

|

D1

|

L

|

|

EMP1

|

25

|

25

|

60

|

10

|

|

EMP1.5*

|

40

|

37

|

80

|

10

|

|

EMP2*

|

50

|

50

|

100

|

10

|

|

EMP3*

|

80

|

75

|

120

|

12

|

|

EMP4*

|

100

|

100

|

155

|

12

|

|

EMP6*

|

150

|

150

|

210

|

12

|

|

EMP9

|

225

|

200

|

260

|

15

|

| EMP12 | 300 |

300

|

360

|

15

|

|

Cat.Ref.

|

DN

|

Thread

|

d

|

L

|

|

PHC0.5/0.75

|

12

|

GL14

|

13.75

|

70

|

|

PHC0.7/0.25

|

15

|

GL14

|

13.75

|

70

|

|

PHC1/1*

|

25

|

GL25

|

24.5

|

90

|

|

PHC1/0.75

|

25

|

GL18

|

17.5

|

90

|

|

PHC1/0.5

|

25

|

GL18

|

17.5

|

90

|

|

PHC1/0.25

|

25

|

GL14

|

13.75

|

90

|

|

PHC1.5/1

|

40

|

GL25

|

24.5

|

100

|

|

PHC1.5/0.75

|

40

|

GL18

|

17.5

|

100

|

|

Cat.Ref.

|

DN

|

Thread

|

d

|

L

|

|

PBHC0.5/0.25

|

12

|

GL14

|

13.75

|

50

|

|

PBHC0.7/0.25

|

15

|

GL14

|

13.75

|

50

|

|

PBHC1/1*

|

25

|

GL25

|

24.5

|

60

|

|

PBHC1/0.75

|

25

|

GL18

|

17.5

|

60

|

|

PBHC1.5/0.75

|

40

|

GL18

|

17.5

|

75

|

|

PBHC2/0.75

|

50

|

GL18

|

17.75

|

100

|